Today’s industries not only rely on investment costs or Capital Costs (CC), but on Total Cost of Ownership (TCO). TCO includes operating & maintenance costs (OMC) in addition to CC. Depending on the period considered, OMC can have a great impact on TCO, therefore reliability & long life of components is vital.

The Flexacier®/Winflex® grid couplings offer this reliability & long life (Flexacier® brand is widely used in French & Spanish speaking countries, Winflex® brand is widely used in English & German speaking countries; Flexacier® & Winflex® represent the same grid coupling ranges); its 100% compact metallic design, coping with harsh environment, can reach 40000 hours or 5 years between 2 maintenance operations.

Its unique design with the grid progressive stiffness allows to absorb every peak torque & shocks, observed for instance at motor start, and reduces vibration. A good summary of the Flexacier®/Winflex® coupling is that it has the torque transmission capacity of a gear coupling, with the same flexibility as an elastomeric coupling.

Elastomeric couplings manufacturers often promote the ‘maintenance free’ ability of these couplings; In fact, these couplings will require frequent maintenance operations (every 6 or 12 months), with an observed life span of 2 years (maximum 3 years in very smooth environments).

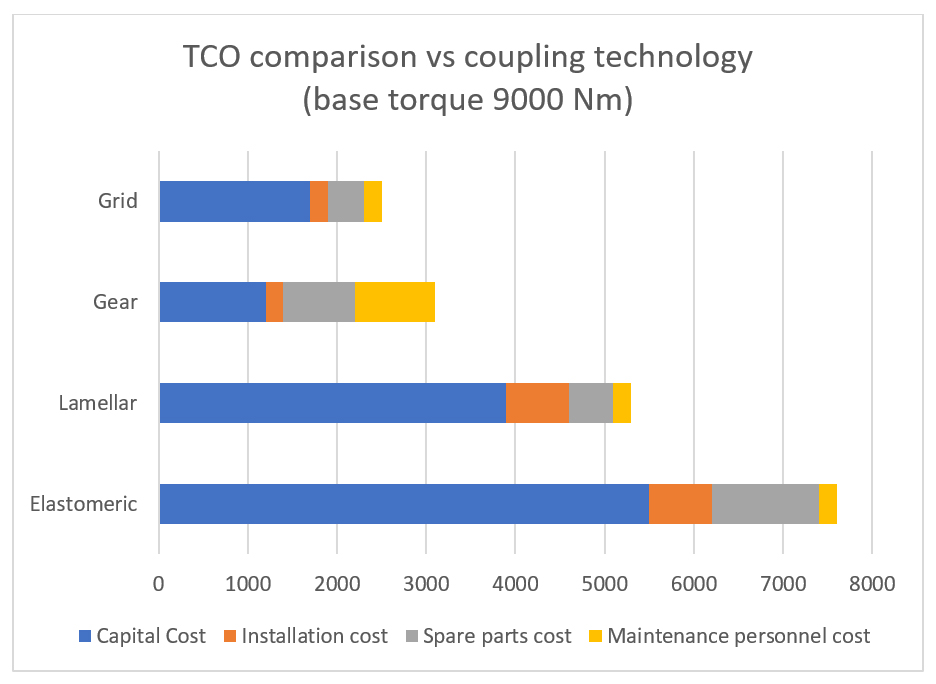

The sketch below provides various TCO’s depending on coupling technology (observed by distributors in France), based on a 9000 Nm coupling rating. Comparison is made between 4 technologies: Elastomeric, Disc, Gear, Grid.

TCO id calculated by adding Capital Cost (CC) (‘Capital Cost’, in blue on the sketch), and Operating & Maintenance Costs (OMC), composed of installation cost (in orange on the sketch), spares cost (in grey on the sketch) and maintenance staff cost (in yellow on the sketch). Additional costs like ‘in service’ operation costs have not been included, as they are non significant on TCO, and technology has no real impact compared to maintenance strategy implemented by a company, so non pertinent for comparison purpose.

OMC comparison for various couplings technology (French distribution)

The CC indicated on the sketch are based on costs observed for western couplings manufacturers. More exotic sourcing is available today to reduce the CC, but for long enough periods (over 2 years), OMC will be significant enough to come to the same conclusion: The Flexacier®/Winflex® coupling has the best result for TCO & is the real ‘maintenance free’ coupling.

Another aspect to be considered, is the ability to be ‘environmentally friendly’. Companies have more & more concern about their social & environmental impact, thus asking the same from their suppliers.

Being environmentally friendly is directly linked to longevity & reliability, of course, as less maintenance means less spare parts & less energy used.

It is also related to recycling & circular economy. Grid couplings are made of metal, 100% recyclable. It uses lubrication of course, so extra care must be taken on sealing (problem is not the lubricant, but the leak), and also lubricant manufacturers make lots of efforts to promote more environmentally friendly greases, sometimes even with ECOLABEL. Worn elastomeric elements might be hardly recyclable.

For instance Grid couplings are now widely accepted for the food & beverage industries, as good alternates to ‘non lubricated’ couplings, or stainless steel couplings. Anti-corrosion or oxidation coatings, that have long been used for the ports & maritime industries (due to the highly salty & corrosive atmospheres), have proven to be compatible with the particular environment of food & beverage industries (with intense cleansing & washing procedures), with unrivalled torque transmission capacities (compared to elastomeric or stainless steel couplings).

CMD Flexacier®/Winflex® coupling with anti-corrosion protection

To conclude, the Flexacier®/Winflex® grid coupling, offering unrivalled compromise between torque transmission, reliability & long life, is today the real maintenance free & eco-friendly coupling.