Marlborough, MA, USA, January 2024. Ruland has released mountable shaft collars with face holes for applications where the shaft collar needs to be directly mounted to a component such as a pulley, sprocket, or metallic plate. The shaft collars are available with drilled face holes that give the user flexibility in mounting hardware, or tapped holes that match the standard screw threading of the collar for ease of installation.

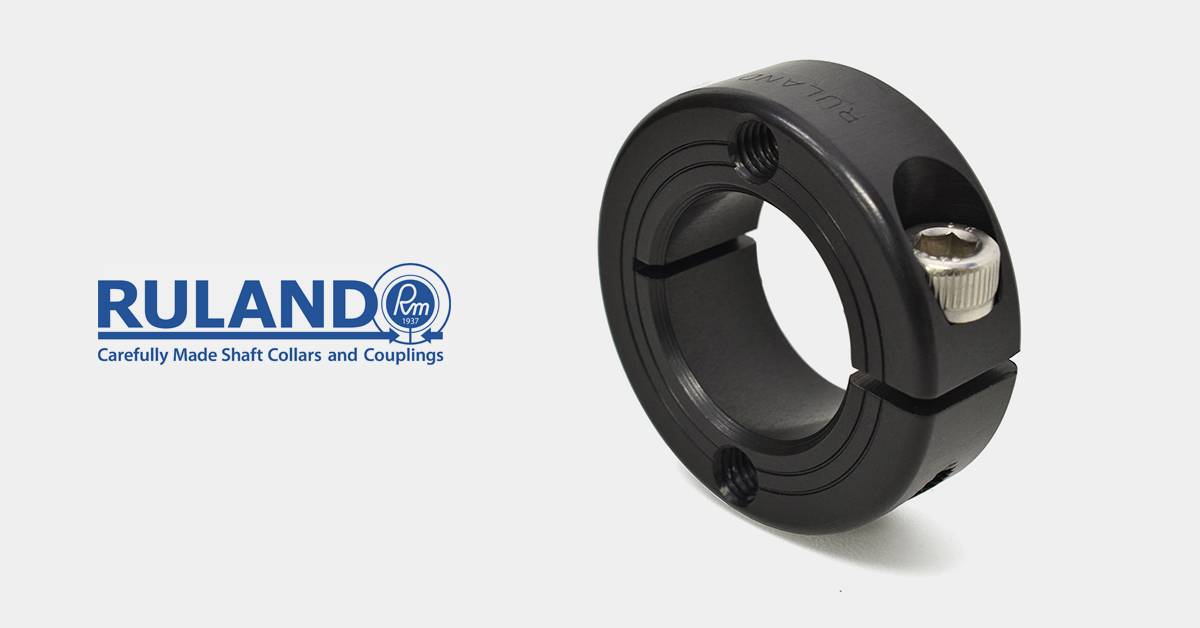

Ruland designs and manufactures face mount shaft collars to have superior fit, finish, and holding power. They have precise face to bore perpendicularity (TIR ≤ 0.05 mm or 0.002 inch), which is critical for mounting applications these shaft collars are typically used in. The groove in the face of the collar identifies the work surface for easy installation. Ruland face mount shaft collars have a burr-free finish, making them an ideal solution for applications in industries such as medical, food, and semiconductor, where contamination is unacceptable. Face mount shaft collars undergo proprietary manufacturing processes to maintain their round bore geometry for tight tolerances, proper installation fit, and improved clamping capabilities.

The different mounting options give designers a wide variety of off-the-shelf products to choose from. Drilled holes allow for a wider variety of inch or metric mounting hardware to be used. Tapped holes provide a direct interface between the collar, screw, and mated component for the most reliable fit. Either configuration can accommodate socket head, set, or button head screws. The face holes are aligned 180 degrees from each other, allowing the user to install the collar in any orientation.

Ruland offers shaft collars with face holes in 1215 lead-free steel for high strength, 2024 aluminium with an anodized finish for lightweight, and 303 stainless steel for corrosion resistance. They are available in one-piece clamp style in bore sizes from 10 mm to 80 mm and 3/8 inch to 3 inches.

Ruland carefully manufactures shaft collars with face holes in its advanced manufacturing facility in Massachusetts, USA, from meticulously selected North American bar stock using proprietary processes. Full product specifications, technical videos, and free 3D CAD files are available on ruland.com.